PCD Tools: Core Tools for High - Efficiency Cutting in Multiple Fields and Guide to Processing Parameters

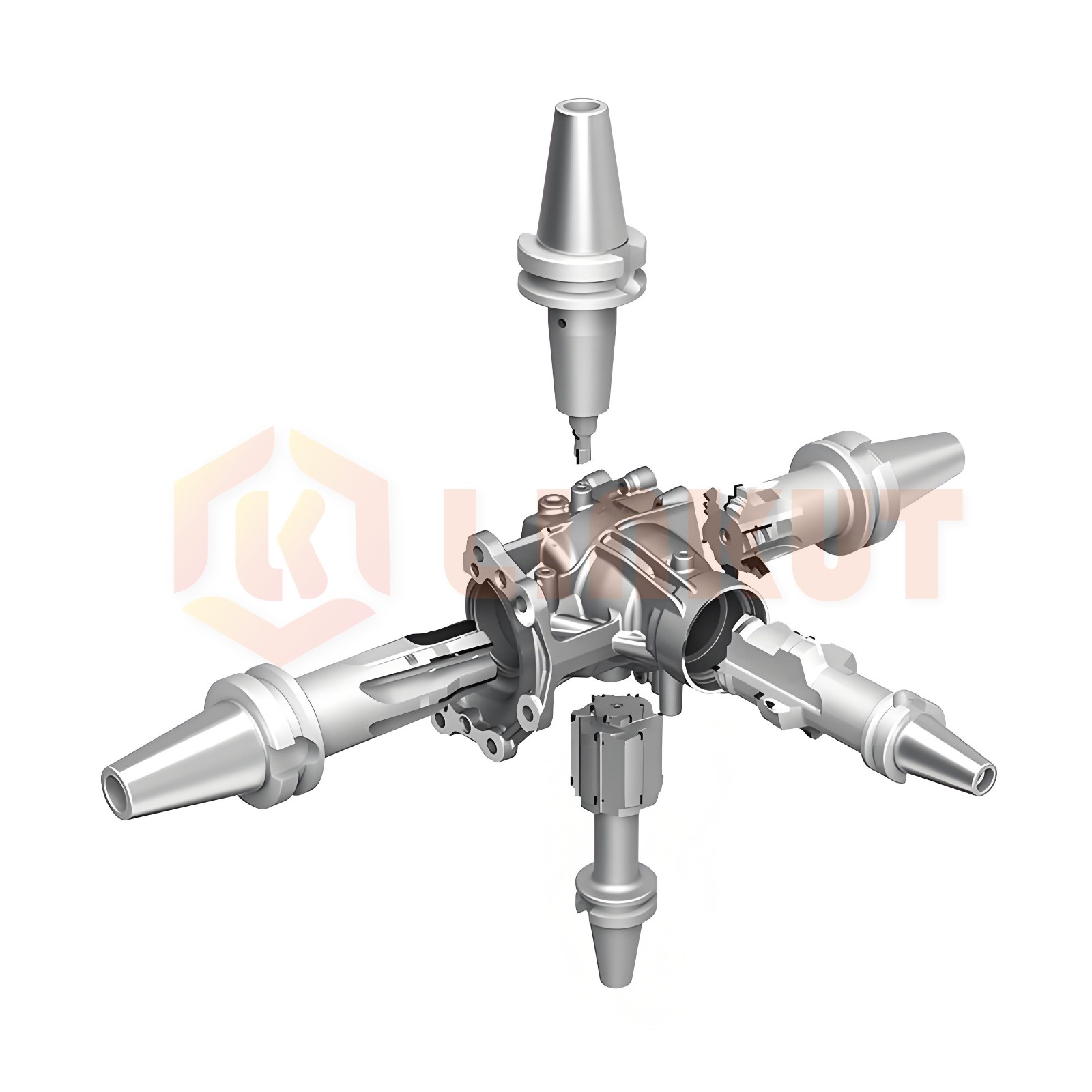

As a leading material in the field of super - hard cutting tools, PCD (Polycrystalline Diamond) tools have become the core tools for modern cutting processes, thanks to their excellent hardness, wear resistance, and cutting performance. Their application scope is constantly expanding, playing an indispensable role in many key fields such as aerospace, automotive manufacturing, and 3C electronics.

In the aerospace field, PCD tools shoulder the important task of processing composite materials. Take CFRP (Carbon Fiber Reinforced Plastic) as an example. This lightweight and high - strength material is commonly used in the manufacturing of aircraft wing beams, as well as the processing of components such as bearings, pump parts, and sleeves. PCD tools can perform precise cutting, ensuring the high precision and reliability of aerospace components, and facilitating the development of the aviation industry towards lightweight and high - performance.

The automotive manufacturing industry is another important application field of PCD tools. Aluminum alloys, with their characteristics of low weight and high strength, are widely used in key automotive components such as pistons, wheels, engine skirts, pinholes, and cylinder blocks. PCD tools perform outstandingly in the processing of such materials, not only significantly improving processing efficiency but also ensuring the surface quality of parts, meeting the stringent requirements of the automotive industry for the precision and consistency of components.

In the 3C industry, as magnesium - aluminum alloys gradually replace traditional materials such as ABS, PC, and zirconia and become the mainstream materials for products such as mobile phone casings, the advantages of PCD tools have been fully demonstrated. Their high - efficiency and precise processing performance provide technical support for the thin - light and delicate design of electronic products.

PCD tools have received widespread acclaim in the market due to their high - efficiency and high - quality processing performance. However, to fully exert their performance advantages, the rational selection of processing parameters is of crucial importance.

Cutting speed is one of the key factors affecting processing quality. If one blindly pursues processing efficiency and sets too high a cutting speed, a large amount of heat will be generated during the cutting process, and the cutting force will increase significantly, thereby accelerating the wear of the tool tip. This situation of "haste makes waste" will not only reduce the service life of the tool but also affect the processing precision and surface quality of the workpiece.

The selection of feed rate cannot be ignored either. An excessive feed rate may exceed the bearing capacity of the tool, causing the tool edge to break and resulting in a rough workpiece surface. While a too - small feed rate can reduce the surface roughness to a certain extent, when it is reduced to a specific threshold, the plastic deformation of the material will intensify, and instead, the roughness will increase. It can be seen that setting the feed rate scientifically and reasonably is an important prerequisite for achieving high - quality processing.

The parameter requirements for PCD tools vary significantly depending on the material being processed. Take the processing of aluminum alloys with LINKUT's PCD tools as an example. The parameter settings differ according to the silicon content in the aluminum alloy:

1)Aluminum alloy (silicon content < 3%)

Milling: linear speed VC 200 - 2000 (m/min), feed per tooth fz 0.02 - 0.4 (mm/t)

Turning: linear speed VC 200 - 3000 (m/min), feed per revolution f 0.05 - 0.2 (mm/rev)

2)Aluminum alloy (silicon content < 12%)

Milling: linear speed VC 150 - 1000 (m/min), feed per tooth fz 0.02 - 0.4 (mm/t)

Turning: linear speed VC 150 - 1000 (m/min), feed per revolution f 0.05 - 0.2 (mm/rev)

3)Aluminum alloy (silicon content < 21%)

Milling: linear speed VC 100 - 800 (m/min), feed per tooth fz 0.02 - 0.4 (mm/t)

Turning: linear speed VC 100 - 800 (m/min), feed per revolution f 0.05 - 0.2 (mm/rev)

The above parameters are the reference standards for LINKUT's PCD tools to process aluminum alloys. It should be noted that PCD tools from different manufacturers may vary in material properties, manufacturing processes, etc. During actual processing, it is recommended that users communicate in depth with the manufacturer to obtain processing parameters that better meet their own needs, ensuring the optimization of processing quality and efficiency.

Previous Article:Core Analysis of PCD Countersink Drill —— LINKUT Aerospace - grade Solution

Next Article: PCBN Tools Revolutionize New Energy Vehicle Direct-Drive Gear Sleeve Processing